The washing tunnel produces almost 300 liters of wastewater per hour, 8 hours a day, with wastewater containing oils and greases. The company, wishing to implement a zero-waste policy by recycling its degreasing effluent, currently has a plant with neutralization, decantation, filter press and vacuum evaporator for clarified effluent, ensuring the recycling of process water. However, this treatment plant is neither functional nor adapted to our Customer’s needs, which is why he hopes to optimize its operation with NISKAE’s know-how and the expertise of its laboratory experts.

Treatment of process water from a degreasing tunnel

Our customer, a leader in France and Europe in metal treatment and coating, has become a major supplier to construction professionals. Its business involves fast-curing powder pre-lacquering of continuous aluminum coils, which requires a prior degreasing stage in a dedicated tunnel. Degreasing consists of spraying an aqueous acid solution to obtain a clean surface and eliminate all dirt generated by the pre-extrusion process. With a view to recycling its process water, our customer wisely turned to NISKAE!

The solution for recycled process water

Neutralize pH with reduced, customized dosing

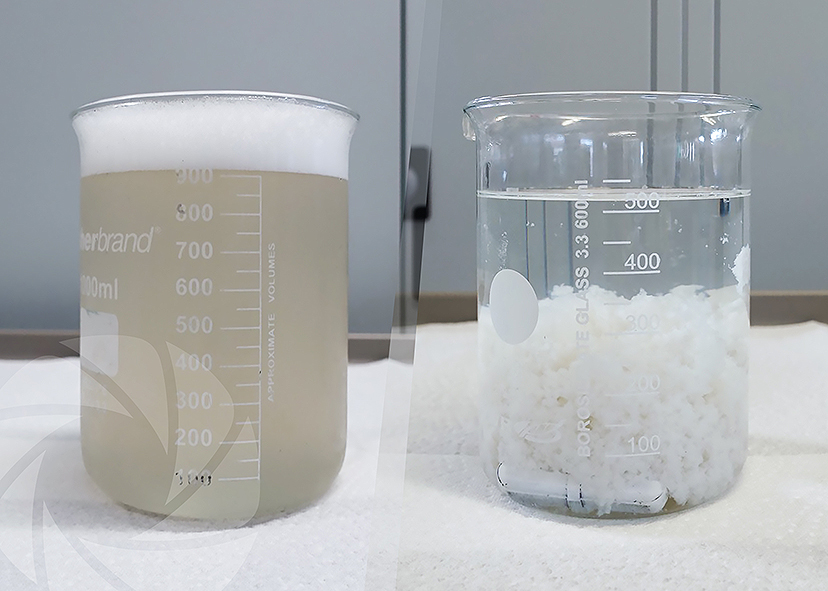

Wastewater samples supplied by our customer were analyzed in the laboratory, after which a flocculation powder formulation was developed.

During the degreasing process, the company uses an aqueous solution which makes the water basic; the primary objective of liquid waste treatment is therefore to neutralize the pH. NISKAE uses hydrochloric acid to neutralize the pH from 12.82 to 7.44. What’s more, with a concentration of 3.00 g/l of our coagulant reagent, the water is virtually demineralized and fully recyclable. In fact, iron and copper concentrations drop from 0.13 mg/L and 0.11 mg/L respectively, to values below 0.01 mg/L. The brown, cloudy solution becomes clear and colorless. Once the waste has been filtered, the water can again be used to feed the degreasing process.

Rejection 0 is achieved with NISKAE’s tailor-made reagent

As the customer wanted to be able to effectively recycle its wastewater from degreasing for its aluminum lacquering activity, NISKAE proposed a coagulation and flocculation treatment capable of making the water reusable. The objective of optimizing the neutralization, decantation and filtration process is thus achieved. What’s more, using the powder formulated by NISKAE is synonymous with numerous advantages, including time and cost savings, in a way that is more respectful of the environment!