Our customer has sent us two samples of its wastewater so that we can develop the coagulant-flocculant reagent best suited to the effluents encountered.

The first sample of MUF glue wash water contained non-negligible concentrations of iron (1.24mg/L) and zinc (0.26mg/L), as well as 0.88% suspended solids (SS). For a minimum reagent dosage of 1.0g/L, we obtain a reduction in iron and zinc, both down to 0.04mg/L. Suspended solids were completely eliminated. What’s more, the solution presented to our Customer generates a low volume of sludge to be evacuated, only 10% of the volume of water to be treated, and the addition of the coagulation reagent does not modify the pH value, thus ensuring its stability.

The sample of resorcinol glue cleaning water also contained significant concentrations of iron (0.46mg/L) and zinc (0.17mg/L), with 0.97% suspended solids. With the same reagent dosage of 1.0g/L, the iron concentration was reduced to below 0.01mg/L and the zinc concentration to 0.01mg/L. Suspended solids are also completely eliminated. The volume of sludge to be evacuated remains low, at just 2 to 3% of the volume of water to be treated, while the pH remains unchanged and stable after addition of the reagent.

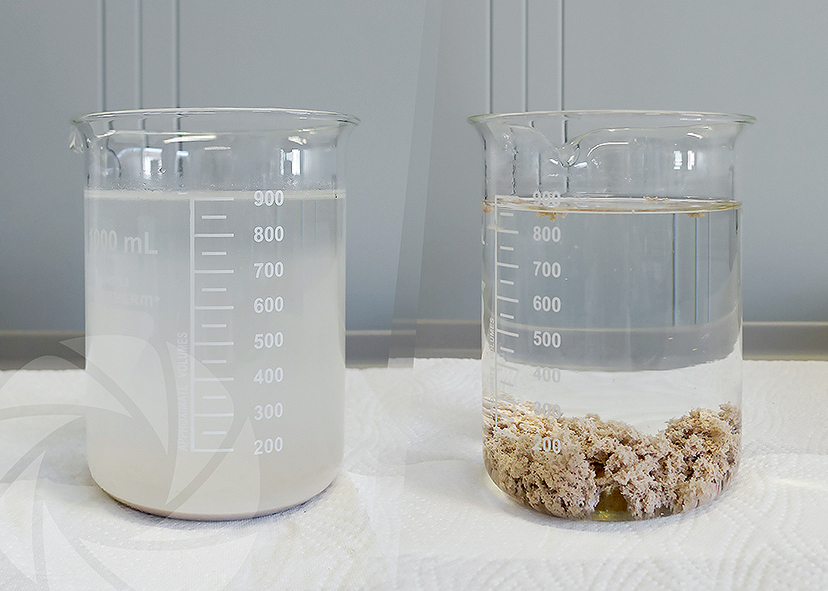

Before treatment, the water from both samples was turbid, whereas after using the coagulant-flocculant formulation developed by NISKAE’s laboratory experts, it is now clean, clear and compliant with regulatory standards for possible discharge or reuse. The resulting sludge is non-sticky and easily dewatered, enabling it to be disposed of as waste.