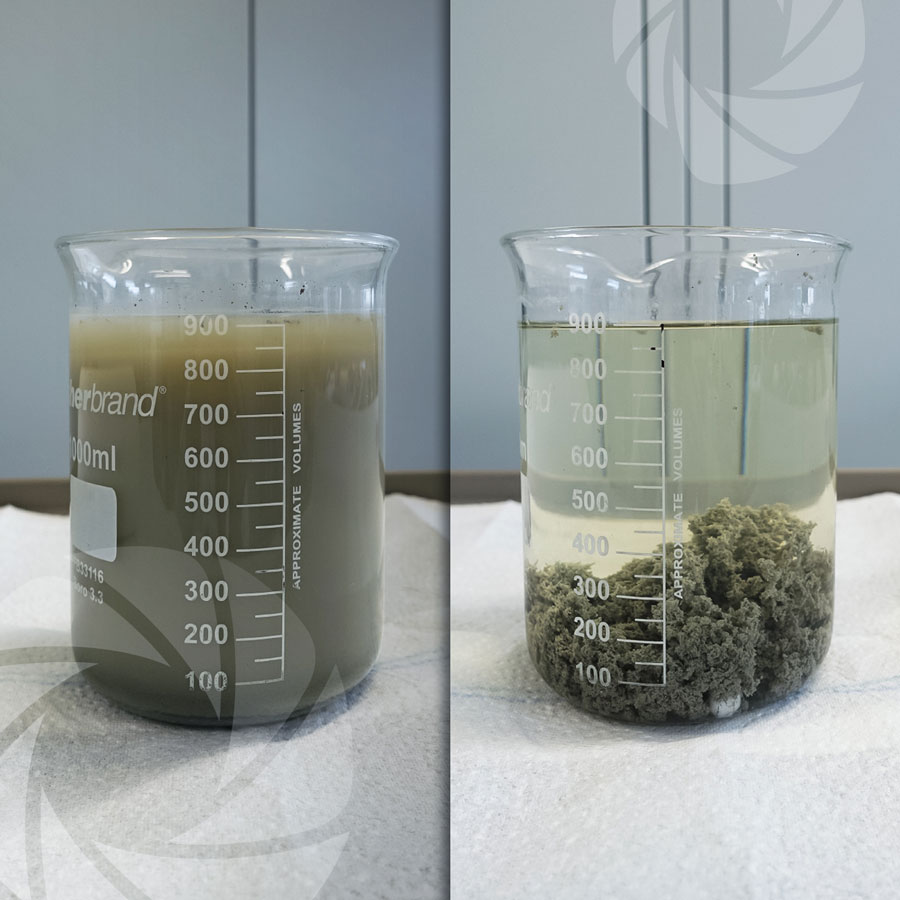

Industrial floor washing wastewater treatment and recycling

An automotive industry parts manufacturer uses a plastic injection process. All injection molding machines generate an oily residue on the floors every day. It also happens that some hoses and hydraulic circuits can cause an accidental oil spil

Context

A semi-automatic microstation and a customized formulation to ensure environment protection

Concerned about the environmental consequences associated with the risks of discharge and environmental pollution, our Client decided to call NISKAE, specialist in the treatment and recycling of industrial wastewater, for a solution adapted for his industrial use. The main goal of this project is to treat the washing water and reuse it. The targeted benefit is therefore multiple, namely the elimination of hazardous storage, the reduction in reprocessing costs, the absence of discharge into the municipal water system and the reduction in water consumption.

- 1 wastewater recuperation tank for emptying of the auto floor scrubbers ;

- 1 wastewater storage tank with a capacity of 500 L ;

- 1 SW100 water treatment reactor ;

- 1 clear water storage tank with a capacity of 500 L. This tank is equipped with a water booster pump and a range of particulate and antibacterial filters for a clean and clear treated water return and at city water pressure.

A solution that is both economic and environmental. Elimination of water storage and a significant reduction in operational costs