Our customer estimates the volume of its wastewater at almost 2m3 per day. Most of this water contains fats. The decanter currently used to treat this water is no longer sufficient for the company’s growing activity. NISKAE was called in to design a mono-reactive product based on the principle of coagulation and flocculation, to bring the water’s properties into line with current standards.

In order to best meet the customer’s requirements, we carried out a series of tests on samples of their wastewater.

Our customer’s washing water is characterized by a high concentration of iron and zinc. The aim of our work is to propose a treatment using the principle of coagulation and flocculation to generate sludge with the pollutants and heavy metals present in this water. The powdered product developed by NISKAE engineers reduced these two concentrations from 3.55 to 1.85 mg/L for iron and from 0.39 to 0.04 mg/L for zinc. In addition, the pH of the initially acidic water was raised from 5.38 to 6.79.

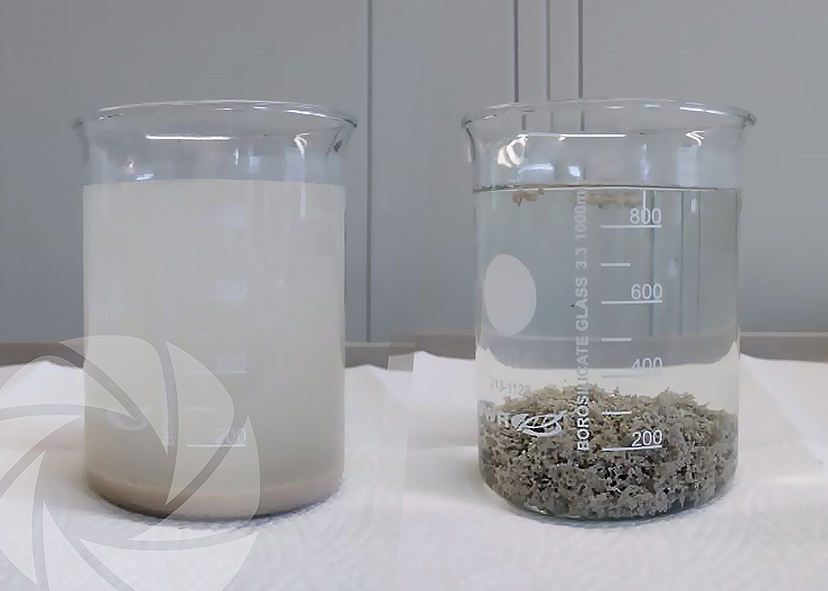

Visually, the solution changed from opaque grey to clear and translucent with the sludge deposited at the bottom of the beaker. What’s more, the sludge is easily filtered and dehydrated, which represents a major advantage in our customer’s wastewater management.