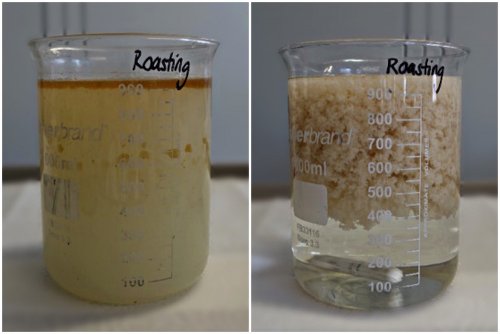

Our chemistry experts took 3 samples of wastewater for laboratory analysis. Specific parameters were found and used to prepare the right coagulant and flocculant. In addition to being effective in small doses - a reduction in product consumption of 20% to 40% compared to conventional products - our pulverulent products are sulfate-free and are available in three pH-value adaptations. Following the new treatment, the customer got a totally clean and clear water.

The manufacturer can now evacuate the treated water or reuse it, while reducing maintenance costs and facilitating logistics. A most profitable investment for the responsible management of wastewater!